Aveva e3d

Elevate your career with E3D expertise through our practical training

Syllabus for Aveva E3D training course

Eligibility Criteria – Fresher’s/ ITI holders/ Diploma/ BE/ Any Draftsman

Discipline- Piping, Mechanical, Chemical, Production, Civil, Structural, Electrical and Instrumentation

Course Duration – 30 days

Detailed Syllabus

1. Introduction to AVEVA E3D:

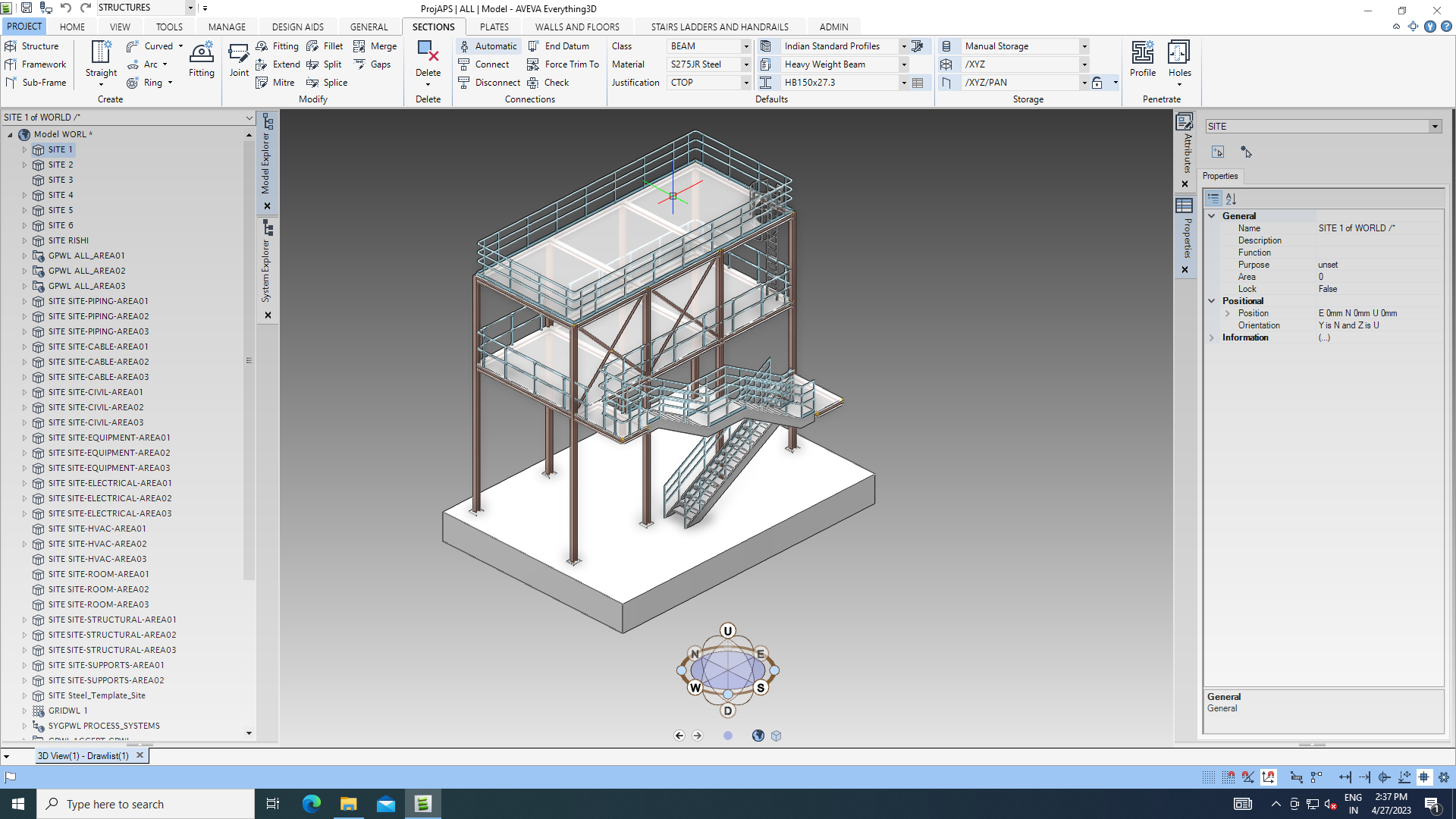

- Overview of the capabilities of AVEVA E3D in the context of plant design

- Introduction to the graphical user interface (GUI) and software architecture of AVEVA E3D

- Overview of the different modules and their functionalities in AVEVA E3D

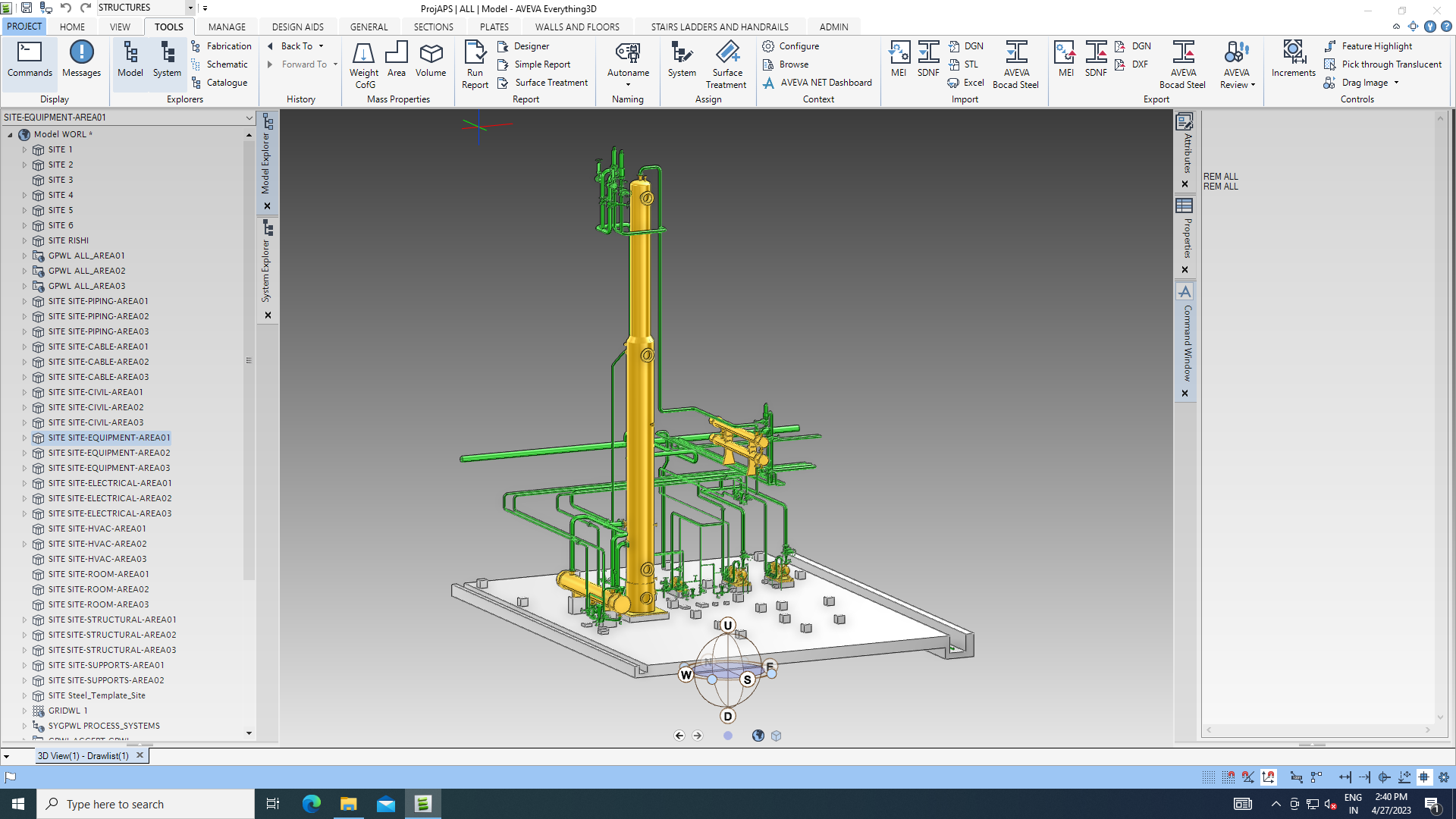

2. 3D modeling:

- Overview of the different modeling techniques available in AVEVA E3D

- Understanding of the different geometric entities used in 3D modeling

- Introduction to 3D modeling concepts such as solid and surface modeling

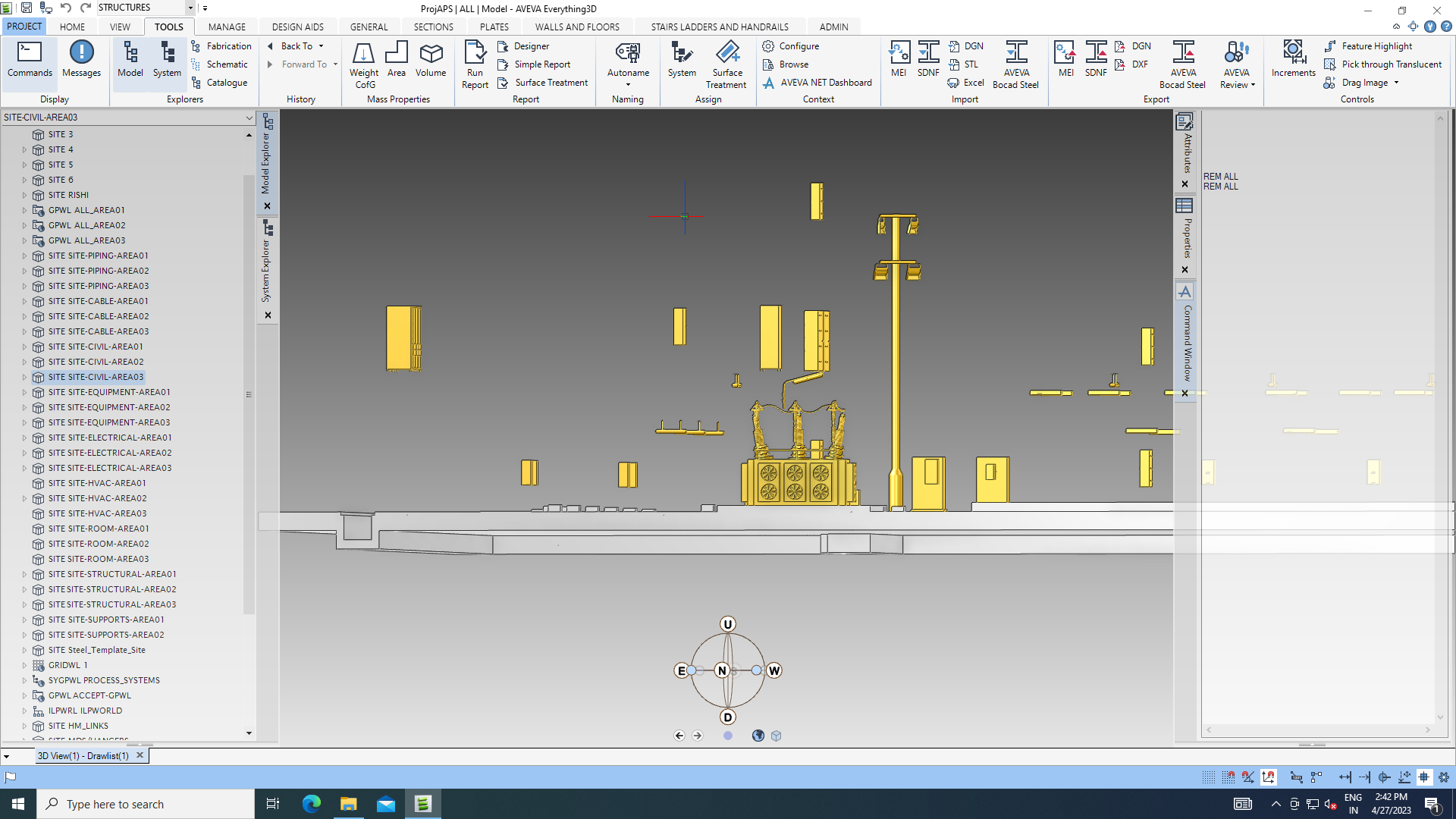

3. Equipment modeling:

- Creating equipment models in AVEVA E3D, including tanks, vessels, pumps, and compressors

- Understanding of equipment properties, including size, orientation, and specifications

- Creating and managing equipment tags and labels

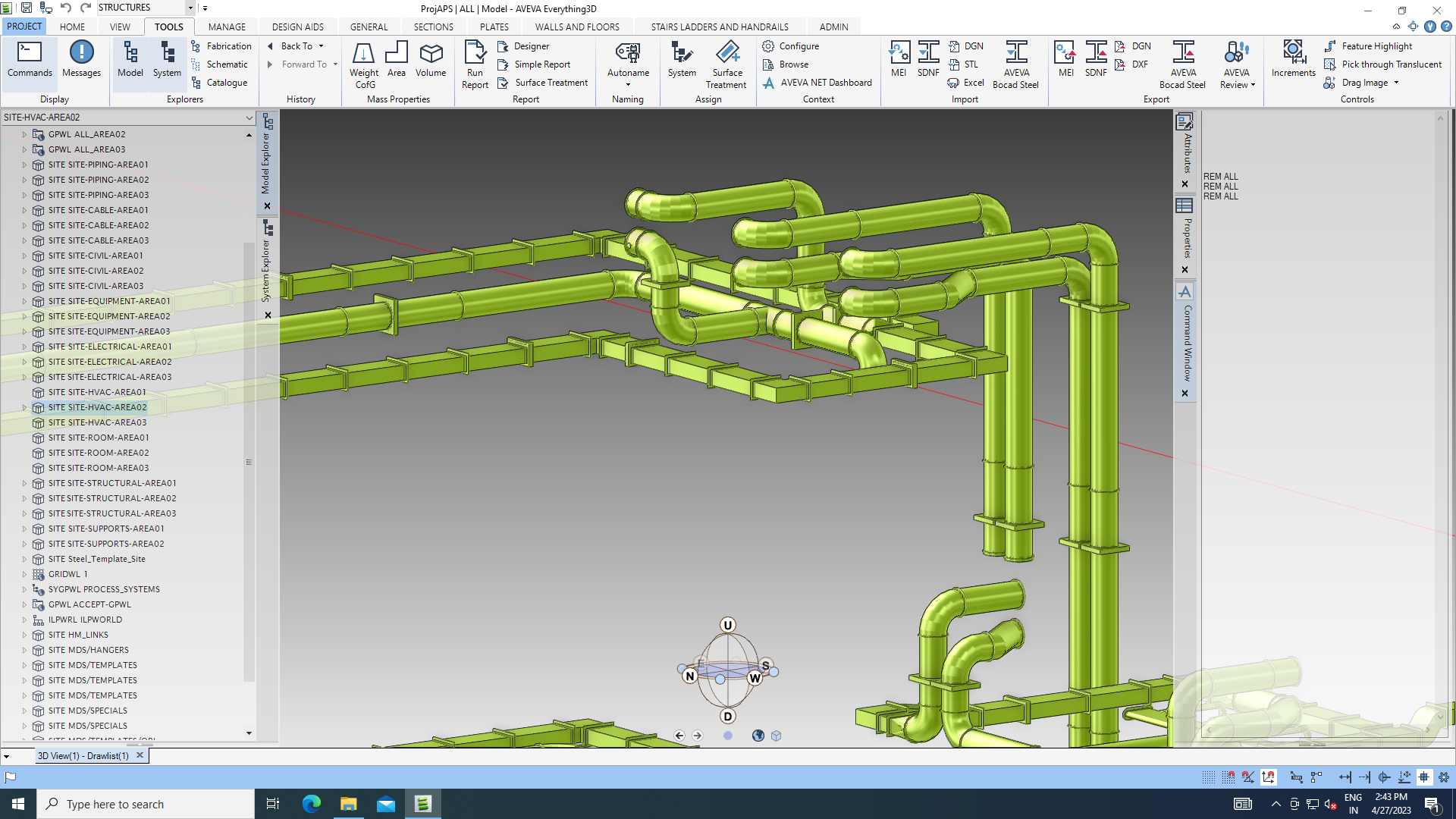

4. Piping modeling: (for Piping discipline)

- Creating piping models in AVEVA E3D, including pipe routing, pipe support, and pipe specifications

- Introduction to piping components and fittings

- Understanding of piping properties, including size, orientation, and specifications

5. Structural modeling: (for Civil & Structural discipline)

- Creating structural models in AVEVA E3D, including steelwork, concrete, and foundations

- Understanding of structural properties, including size, orientation, and specifications

- Creating and managing structural tags and labels

6. Electrical modeling: (for Electrical discipline)

- Creating electrical models in AVEVA E3D, including cable routing, tray routing, and equipment modeling

- Understanding of electrical properties, including size, orientation, and specifications

- Creating and managing electrical tags and labels

7. Instrumentation modeling: (for Instrumentation discipline)

- Creating instrumentation models in AVEVA E3D, including instrument specifications, instrument loops, and cable routing

- Understanding of instrumentation properties, including size, orientation, and specifications

- Creating and managing instrumentation tags and labels

8. Drafting:

- Creating 2D drawings and documents from 3D models in AVEVA E3D, including isometrics, GA drawings, and P&IDs

- Understanding of drafting concepts and standards

- Customizing drawing templates and styles

9. Clash detection:

- Using AVEVA E3D to detect and resolve clashes between different elements of the plant design

- Understanding of clash detection concepts and strategies

- Generating reports and resolving clashes in AVEVA E3D.

What is E3D software?

AVEVA Everything3D (E3D) is a software platform for plant design and engineering, developed by AVEVA, a British multinational information technology company. E3D software is specifically designed for the oil and gas, chemical, power, and marine industries, among others, to support their engineering and design needs for large-scale projects.

E3D provides a comprehensive 3D modeling environment for the creation of process plant designs and supports various disciplines such as piping, equipment, structural, and electrical. The software allows users to create and manage piping and instrumentation diagrams (P&IDs), generate 3D models of equipment and piping systems, and generate 2D drawings and reports such as isometric drawings and bills of materials.

E3D is known for its advanced features such as intelligent piping routing, accurate material take-off (MTO), stress analysis and clash detection. It also has a range of functionalities for multi-discipline collaboration, including project management tools and the ability to integrate with other software applications such as AutoCAD and Microsoft Excel.

What are the applications of E3D?

AVEVA Everything3D (E3D) is a versatile software platform that has a wide range of applications across various industries. Here are some examples of the applications of E3D:

- Oil and Gas Industry: E3D is commonly used in the oil and gas industry for the design of process plant facilities, including refineries, petrochemical plants, and offshore platforms.

- Chemical Industry: E3D is also used in the chemical industry for the design of production plants for chemicals, fertilizers, and other products.

- Power Generation Industry: E3D can be used to design power generation plants, including thermal power plants, nuclear power plants, and renewable energy facilities.

- Marine Industry: E3D is used in the design of marine vessels, including cargo ships, cruise liners, and offshore drilling rigs.

- Mining Industry: E3D can be used to design processing plants for mining and minerals, including metal refining plants, ore processing plants, and mineral processing facilities.

In general, E3D can be used in any industry that requires large-scale plant design and engineering. The software can support the entire design process, from the initial concept and feasibility studies to detailed design, construction, and maintenance. It provides advanced features for collaboration and integration with other software applications, enabling multi-disciplinary teams to work together more effectively.

Role of E3D Designer

The role of an AVEVA Everything3D (E3D) designer typically involves creating and modifying 3D models of plant facilities and equipment using the E3D software platform. Here are some of the key responsibilities and tasks that an E3D designer may be involved in:

- Piping Design: E3D designers are responsible for creating and designing piping systems that meet the project requirements, including selecting appropriate fittings and accessories, determining the pipe routing and size, and ensuring that the design complies with safety and regulatory standards.

- Equipment Design: E3D designers may also be involved in the design of equipment such as tanks, vessels, pumps, and compressors. This includes creating 3D models of the equipment and ensuring that they are integrated into the overall plant design.

- Structural Design: E3D designers may also work on the structural design of plant facilities, including the design of support structures for piping and equipment.

- Collaboration: E3D designers are expected to collaborate with other members of the design team, including engineers, project managers, and other designers, to ensure that the project requirements are met and that the design is delivered on time and within budget.

- Quality Control: E3D designers are responsible for ensuring that the design meets the required quality standards, including accuracy, completeness, and compliance with safety and regulatory requirements.

- Documentation: E3D designers are expected to create documentation for the design, including 2D drawings, isometric drawings, and bills of materials.

Overall, an E3D designer plays a critical role in the design and engineering of large-scale plant facilities, ensuring that the design meets the project requirements and that the final product is safe, efficient, and compliant with regulatory standards.

Job opportunities for E3D Designer

There are several job opportunities available for AVEVA Everything3D (E3D) designers across various industries, including:

- Oil and Gas Industry: E3D designers can find employment opportunities in the oil and gas industry, working for companies that design and build processing plants, refineries, and offshore platforms.

- Chemical Industry: The chemical industry also employs E3D designers for the design and engineering of chemical production plants.

- Power Generation Industry: E3D designers can find employment opportunities in the power generation industry, designing thermal power plants, nuclear power plants, and renewable energy facilities.

- Marine Industry: The marine industry employs E3D designers for the design of marine vessels, including cargo ships, cruise liners, and offshore drilling rigs.

- Mining Industry: E3D designers can also find employment opportunities in the mining industry, designing processing plants for metal refining, ore processing, and mineral processing.

In addition to these industries, E3D designers may also find employment opportunities in engineering and design firms that specialize in plant design and engineering. Some of the job titles that E3D designers may hold include Piping Designer, Equipment Designer, Structural Designer, and 3D CAD Designer.

Overall, the demand for E3D designers is expected to remain strong in industries that require large-scale plant design and engineering. The increasing emphasis on safety, efficiency, and compliance with regulatory standards is expected to drive the demand for skilled E3D designers.

Company names who recruit E3D designers

There are several companies that recruit AVEVA Everything3D (E3D) designers across various industries. Some of the companies that may hire E3D designers include:

- Oil and Gas Industry: Shell, ExxonMobil, BP, Chevron, Total, and ConocoPhillips.

- Chemical Industry: Dow Chemical, BASF, DuPont, and Huntsman.

- Power Generation Industry: GE Power, Siemens Energy, EDF Energy, and Duke Energy.

- Marine Industry: Carnival Cruise Line, Royal Caribbean International, and Norwegian Cruise Line.

- Mining Industry: BHP Billiton, Rio Tinto, and Vale.

In addition to these companies, there are many engineering and design firms that specialize in plant design and engineering and may hire E3D designers. Some of these firms include Bechtel, Fluor, Jacobs Engineering, Worley, and Wood Group.

Overall, there are many opportunities available for skilled E3D designers in industries that require large-scale plant design and engineering.

Some examples of Indian companies

There are several Indian companies that recruit AVEVA Everything3D (E3D) designers, especially in the engineering, procurement, and construction (EPC) sector. Some of these companies include:

- Larsen & Toubro (L&T): L&T is one of the largest EPC companies in India, with a strong presence in the oil and gas, petrochemical, power, and infrastructure sectors. L&T employs a large number of E3D designers for its engineering and design projects.

- Reliance Industries: Reliance Industries is a major player in the oil and gas, petrochemical, and refining sectors in India. Reliance Industries has used E3D extensively for the design and engineering of its large-scale petrochemical and refining projects.

- Tata Projects: Tata Projects is another major EPC company in India, with a strong presence in the power, infrastructure, and industrial sectors. Tata Projects has used E3D for the design and engineering of its projects, including power plants, airports, and metro rail systems.

- Essar Projects: Essar Projects is a leading EPC company in India, with a focus on the oil and gas, power, and infrastructure sectors. Essar Projects has used E3D for the design and engineering of its large-scale projects, including refineries, LNG terminals, and power plants.

- Engineers India Limited (EIL): EIL is a public sector EPC company in India, with a focus on the oil and gas, petrochemical, and infrastructure sectors. EIL has used E3D for the design and engineering of its projects, including refineries, petrochemical plants, and pipelines.

Overall, there are many opportunities available for skilled E3D designers in Indian companies that are involved in large-scale plant design and engineering projects.

Future prospect for E3D

The future prospects for AVEVA Everything3D (E3D) software are promising, as it is a comprehensive 3D design and engineering tool that offers a wide range of capabilities. Here are some of the key factors that indicate a positive future for E3D:

- Increasing demand for plant design and engineering: The demand for large-scale plant design and engineering is expected to continue to grow, driven by factors such as urbanization, industrialization, and the need for energy and infrastructure development. This is likely to drive the demand for tools like E3D that enable efficient and accurate design and engineering of complex plants.

- Emphasis on safety and compliance: There is an increasing emphasis on safety and compliance with regulatory standards in the design and engineering of plants. E3D offers features that enable designers to ensure compliance with safety and regulatory requirements, which is expected to make it a preferred tool for plant design and engineering.

- Advancements in technology: As technology continues to evolve, E3D is expected to incorporate new features and capabilities that enable designers to work more efficiently and accurately. For example, the integration of artificial intelligence and machine learning can enable designers to optimize designs and reduce errors.

- Integration with other software tools: E3D can be integrated with other software tools, such as AVEVA PDMS and AVEVA Engineering, which enables seamless collaboration and transfer of data between different stages of the design and engineering process. This integration is expected to make E3D a preferred tool for plant design and engineering.

Overall, the future prospects for AVEVA E3D are positive, as it offers a comprehensive and advanced tool for plant design and engineering that is likely to continue to be in high demand in various industries.