Aveva pdms

Master PDMS for precise 3D modeling with our comprehensive training

AVEVA PDMS training course

Eligibility Criteria – Fresher’s/ ITI holders/ Diploma/ BE/ Any Draftsman

Discipline – Piping, Mechanical, Chemical, Production, Civil, Structural, Electrical and Instrumentation

Course Duration – 30 days

Detailed Syllabus

1. Introduction to PDMS:

- Overview of Aveva PDMS software and its capabilities

- Role of PDMS in process plant design and engineering

- Benefits of using PDMS for plant design and engineering

2. 3D modeling:

- Techniques for 3D modeling in PDMS, including wireframe, surface, and solid modeling

- Use of primitives, transforms, and Boolean operations in 3D modeling

- Best practices for efficient and accurate 3D modeling in PDMS

- Model Review

3. Equipment modeling:

- Creating equipment models in PDMS, including tanks, vessels, pumps, and compressors

- Equipment modeling techniques, including placement, alignment, and specification

- Best practices for efficient and accurate equipment modeling in PDMS

4. Piping modeling: (for Piping discipline)

- Creating piping models in PDMS, including pipe routing, pipe support, and pipe specifications

- Piping modeling techniques, including routing options, bends, reducers, and flanges

- Best practices for efficient and accurate piping modeling in PDMS

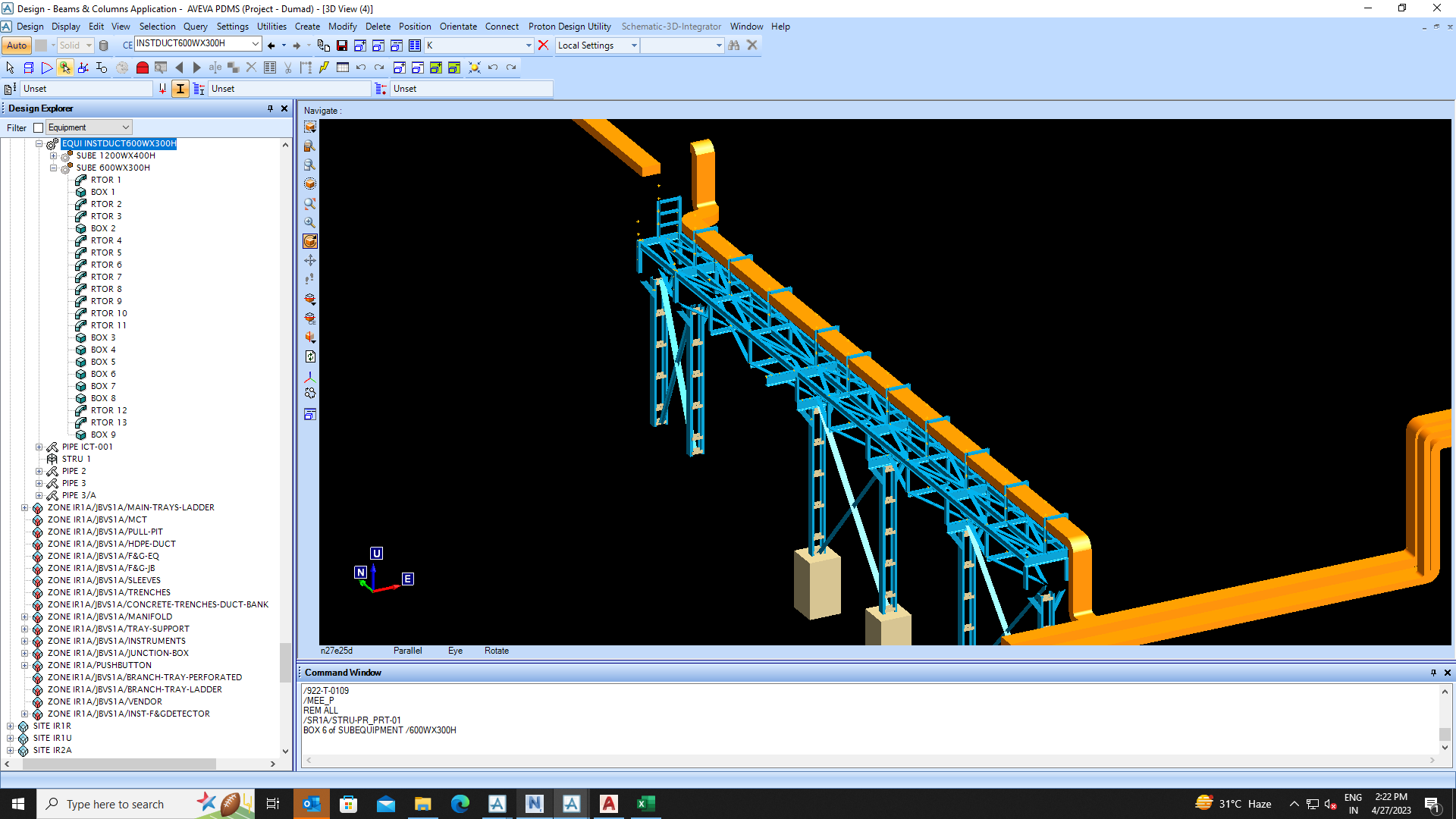

5. Structural modeling: (for Civil & Structural discipline)

- Creating structural models in PDMS, including steelwork, concrete, and foundations

- Structural modeling techniques, including placement, alignment, and specification

- Best practices for efficient and accurate structural modeling in PDMS

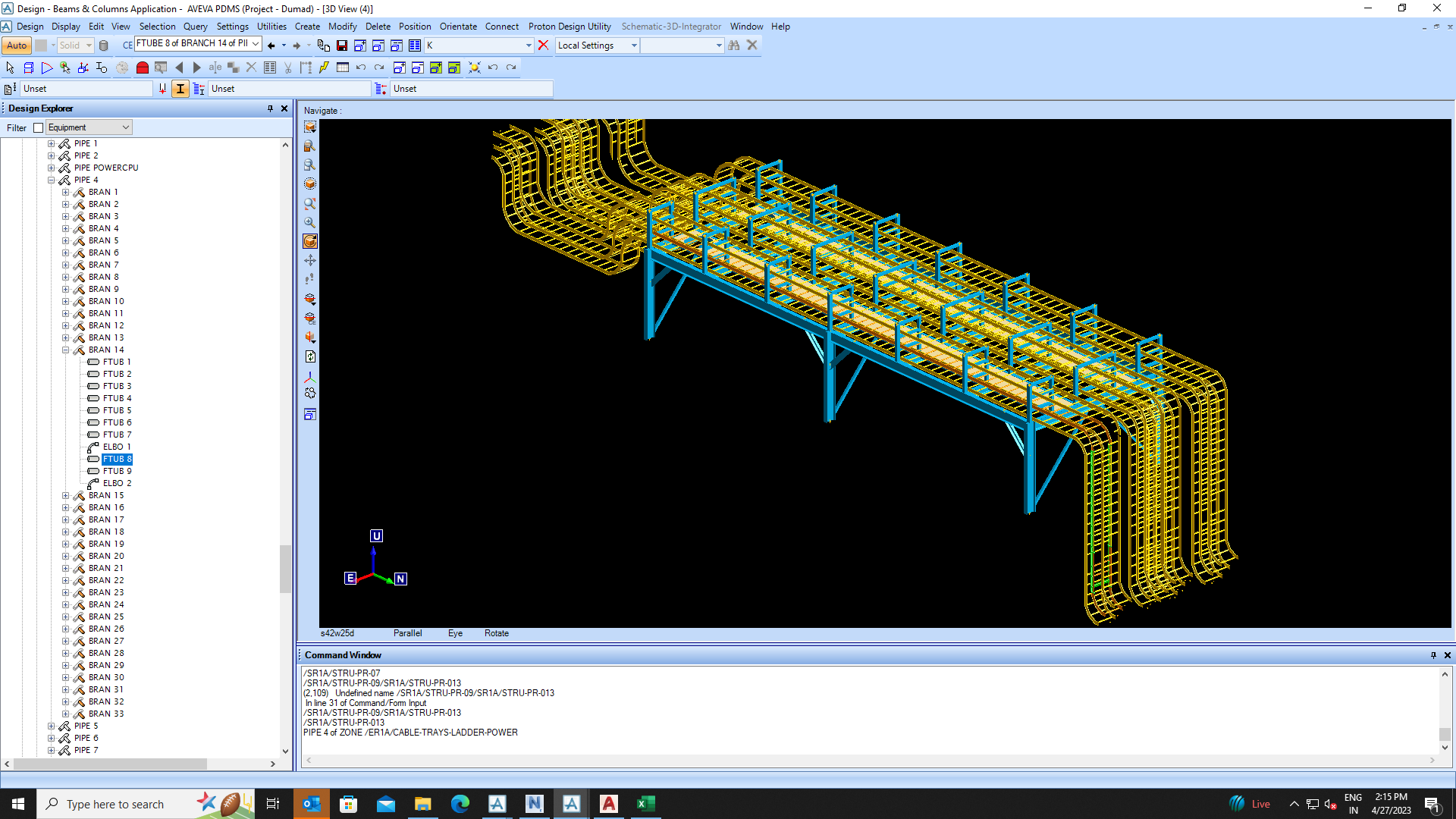

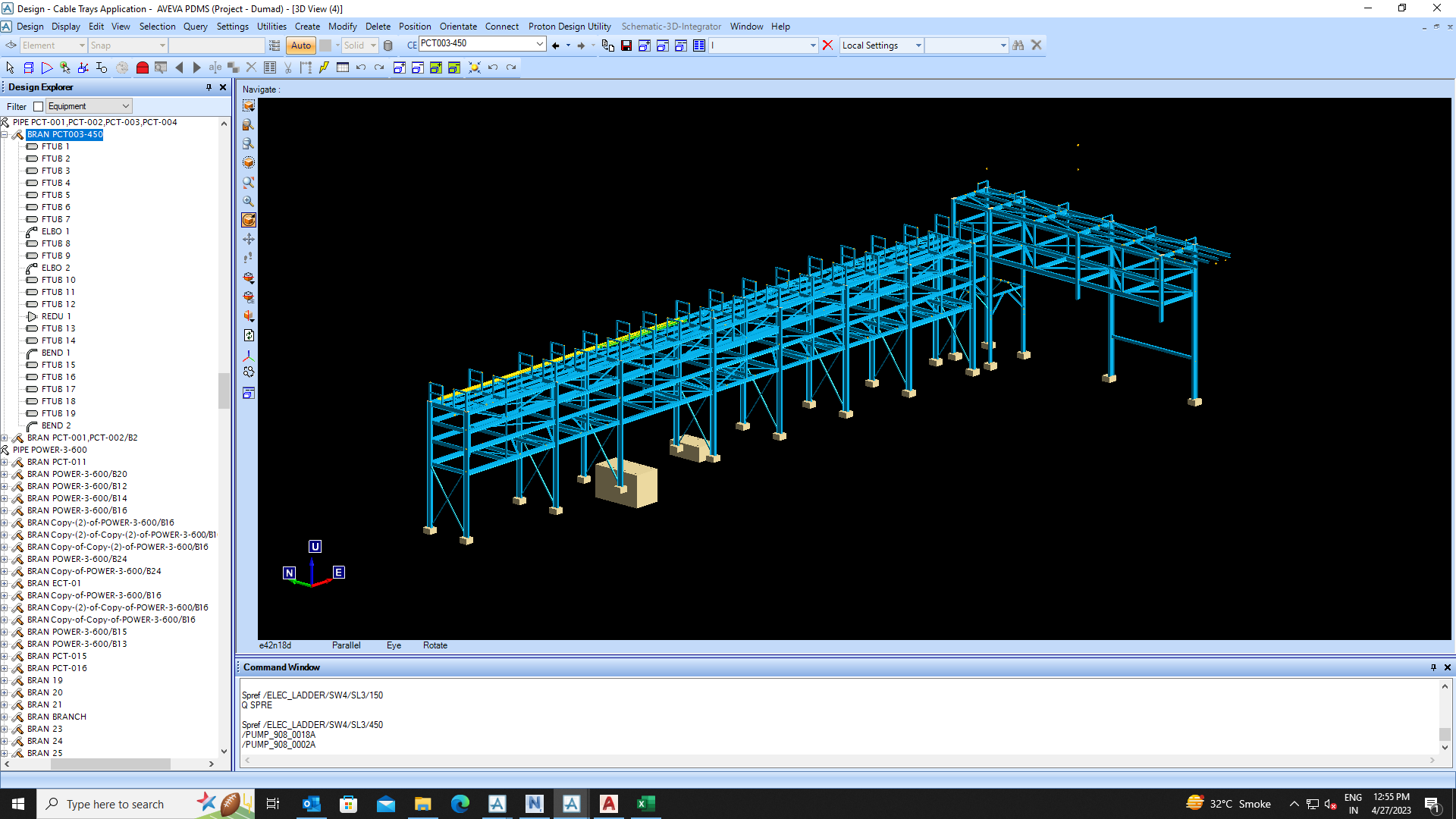

6. Electrical modeling: (for Electrical discipline)

- Creating electrical models in PDMS, including cable routing, tray routing, and equipment modeling

- Electrical modeling techniques, including placement, alignment, and specification

- Best practices for efficient and accurate electrical modeling in PDMS

7. Instrumentation modeling: (for Instrumentation discipline)

- Creating instrumentation models in PDMS, including instrument specifications, instrument loops, and cable routing

- Instrumentation modeling techniques, including placement, alignment, and specification

- Best practices for efficient and accurate instrumentation modeling in PDMS

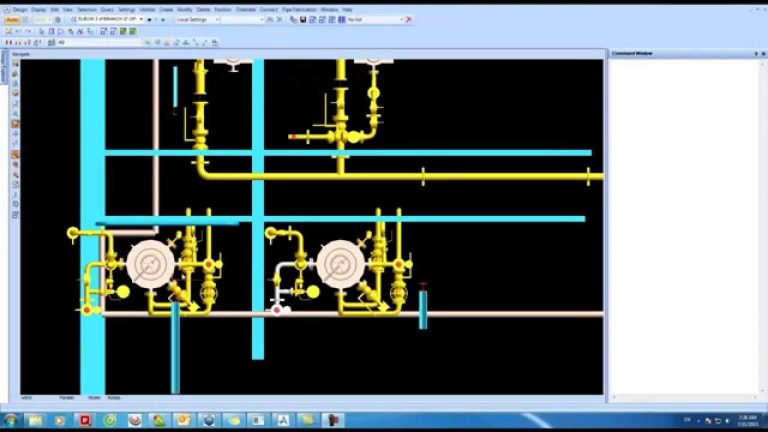

8. Drafting:

- Creating 2D drawings and documents from 3D models in PDMS, including isometrics, GA drawings, and P&IDs

- Drafting techniques, including annotation, dimensioning, and labeling

- Best practices for efficient and accurate drafting in PDMS

9. Clash detection:

- Using PDMS to detect and resolve clashes between different elements of the plant design

- Clash detection techniques, including spatial and interference checking

- Best practices for efficient and accurate clash detection in PDMS

What is PDMS?

PDMS stands for Plant Design Management System, which is a 3D computer-aided design software that is widely used in the process plant design industry. PDMS allows engineers and designers to create and manage 3D models of process plants, including structures, equipment, and piping systems.

PDMS provides a comprehensive set of tools and features to create accurate and detailed plant designs, including tools for 3D modeling, clash detection, isometric drawing creation, and project management. The software is highly customizable and can be tailored to suit the needs of specific projects or industries.

PDMS is developed and maintained by Aveva Group plc, a British multinational engineering and software company. The software is widely used by engineering and construction firms, plant operators, and owner-operators across industries like oil and gas, chemical, and power generation.

Overall, PDMS is a powerful tool for process plant design that helps engineers and designers to optimize their designs, minimize errors, and streamline project workflows.

What are the applications of PDMS?

PDMS has a wide range of applications in the process plant design industry, including:

- Process Plant Design: PDMS is used to create 3D models of process plants, including structures, equipment, and piping systems. This enables engineers and designers to visualize the plant design and identify potential issues early in the design process.

- Equipment Design: PDMS can be used to design and model complex equipment, such as tanks, vessels, and heat exchangers. The software allows designers to customize equipment components and optimize their design for performance and safety.

- Piping Design: PDMS provides a comprehensive set of tools for piping design, including routing and specification tools, isometric drawing creation, and clash detection. The software enables designers to create accurate and detailed piping systems that meet industry standards and project requirements.

- Project Management: PDMS includes project management tools that allow project teams to collaborate, manage project data, and track progress. The software can also be integrated with other project management tools and software.

- Maintenance and Operations: PDMS can be used to create as-built models of process plants that can be used for maintenance and operations. The software allows plant operators to visualize the plant layout and identify potential maintenance issues.

Overall, PDMS is a versatile tool that has a wide range of applications in the process plant design industry. The software helps to streamline project workflows, minimize errors, and optimize plant design and performance.

Role of PDMS Designer

The role of a PDMS (Plant Design Management System) Designer is to create accurate 3D models of process plants using the PDMS software. The PDMS Designer is responsible for the design, modeling, and documentation of various elements of a process plant, including structures, equipment, and piping systems. Some of the specific responsibilities of a PDMS Designer may include:

- Developing and reviewing project design specifications and requirements.

- Creating and modifying 3D models of process plants, equipment, and piping systems.

- Collaborating with other members of the project team, including engineers, designers, and drafters, to ensure the accuracy and completeness of the design.

- Conducting clash detection and resolving interferences between different plant elements.

- Creating and reviewing isometric drawings, material take-offs, and other design documentation.

- Ensuring compliance with industry standards and project requirements.

- Participating in project meetings and communicating progress and issues to the project team.

- Providing technical support and guidance to other members of the project team.

Overall, the role of a PDMS Designer is critical to the success of a process plant design project. The designer’s expertise in PDMS modeling and design is essential for creating accurate and detailed 3D models that meet project requirements and industry standards.

Job opportunities for PDMS designer

PDMS (Plant Design Management System) designers are in high demand in the process plant design industry, and there are many job opportunities available for individuals with expertise in PDMS design and modeling. Some of the job titles that may be available for PDMS designers include:

- PDMS Designer

- Piping Designer

- Process Engineer

- Mechanical Designer

- Structural Designer

- Electrical Designer

- Instrumentation Designer

- Project Engineer

- Project Manager

- CAD/BIM Manager

These job titles may vary depending on the specific industry and project requirements. Some of the industries that typically require PDMS designers include oil and gas, chemical, pharmaceuticals, and power generation. There are also opportunities to work for engineering and construction firms, plant operators, and owner-operators.

PDMS designers may work in a variety of settings, including design offices, construction sites, and plant facilities. The job may require occasional travel and fieldwork, particularly during construction and commissioning phases of a project.

Overall, there are many job opportunities available for PDMS designers, and the demand for skilled designers is likely to continue to grow as process plant design becomes increasingly complex and requires more sophisticated modeling and design tools.

Company names who recruit PDMS designers

There are many companies that hire PDMS (Plant Design Management System) designers for their process plant design projects. Here are some of the well-known companies that frequently hire PDMS designers:

- Bechtel

- Fluor Corporation

- Jacobs Engineering Group

- WorleyParsons

- TechnipFMC

- Aker Solutions

- Wood Group

- McDermott International

- KBR

- Saipem

These companies operate in a variety of industries, including oil and gas, chemical, pharmaceuticals, and power generation. However, there are many other companies that may also hire PDMS designers, depending on the specific project requirements and industry needs. It’s worth noting that many smaller engineering and construction firms may also require PDMS designers for their projects, so it’s a good idea to research companies in your area that specialize in process plant design.

Some examples of Indian companies

There are many companies that hire PDMS (Plant Design Management System) designers for their process plant design projects. Here are some of the well-known companies that frequently hire PDMS designers:

- Bechtel

- Fluor Corporation

- Jacobs Engineering Group

- WorleyParsons

- TechnipFMC

- Aker Solutions

- Wood Group

- McDermott International

- KBR

- Saipem

These companies operate in a variety of industries, including oil and gas, chemical, pharmaceuticals, and power generation. However, there are many other companies that may also hire PDMS designers, depending on the specific project requirements and industry needs. It’s worth noting that many smaller engineering and construction firms may also require PDMS designers for their projects, so it’s a good idea to research companies in your area that specialize in process plant design.