piping design engineering

Our Piping Design Engineering course provides real-world case studies and expert instruction to help you enhance your skills and expand your knowledge in piping design.

Piping Design Engineering course

Eligibility Criteria –

BE / Diploma in Mechanical, Chemical & Production

Course Duration – 30 days

Detailed Syllabus

1. Introduction to Piping Design Engineering:

- Overview of piping systems and their role in different industries

- Types of pipes and fittings used in piping systems

- Piping standards and codes, including ASME, ANSI, API, and ASTM

- Safety considerations for designing and operating piping systems

2. Fundamentals of Piping Design:

- Pipe sizing and selection criteria for different applications

- Pressure drop calculations and their impact on system performance

- Flow rate calculations and their impact on system performance

- Hydraulic analysis and its importance in piping design

3. Pipe Fittings and Valves:

- Types of fittings and valves used in piping systems

- Selection criteria for fittings and valves

- Design considerations for fittings and valves

- Effects of fittings and valves on pressure drop and flow rate

4. Pipe Support and Anchorage:

- Types of supports and their functions in piping systems

- Selection criteria for pipe supports

- Design considerations for pipe support systems

- Pipe stress analysis and its importance in piping design

5. Piping Materials:

- Types of materials used for piping systems, including metals, plastics, and composites

- Properties of different piping materials and their advantages and disadvantages

- Selection criteria for piping materials based on application requirements

6. Piping Drawings and Documentation:

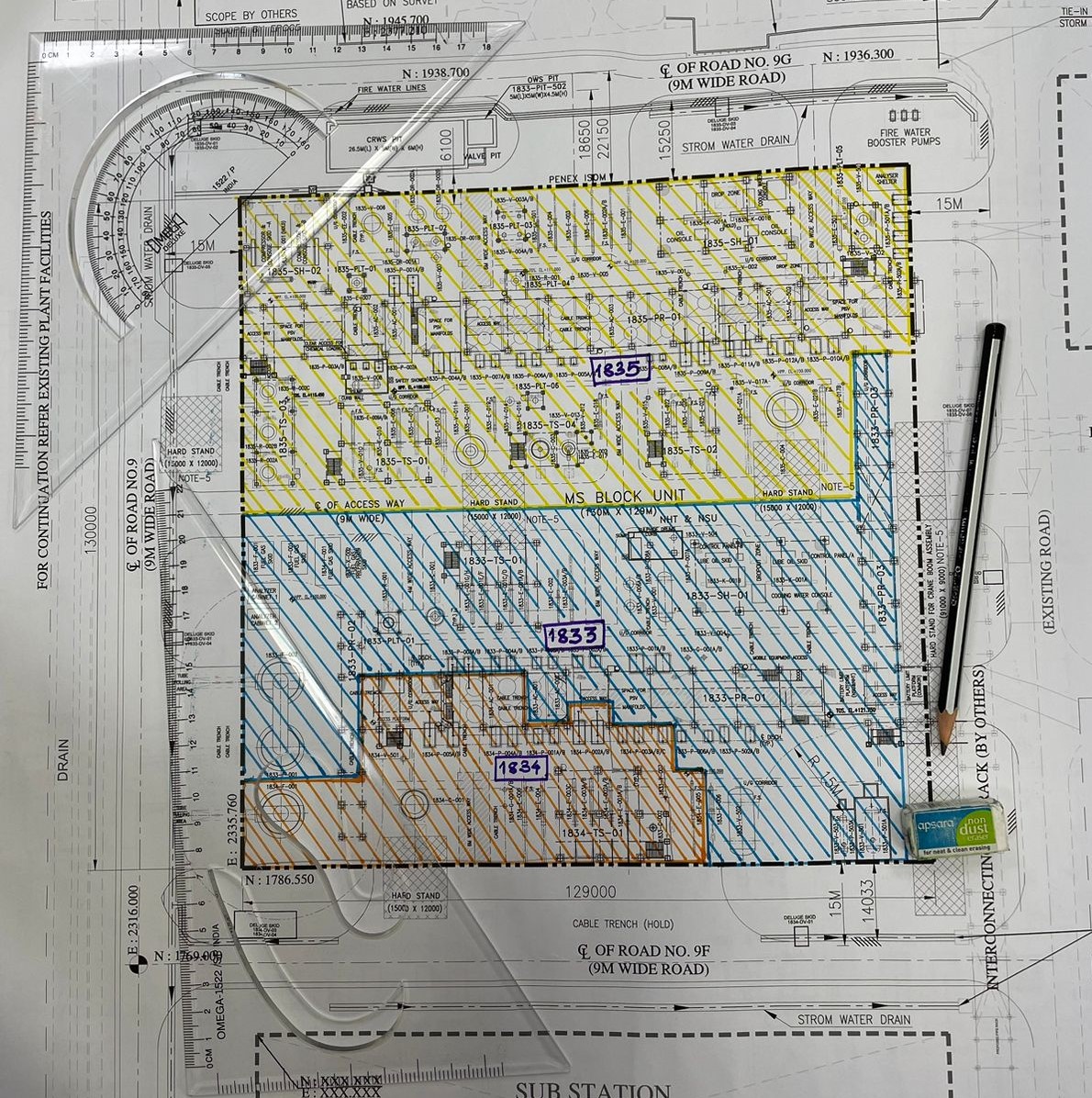

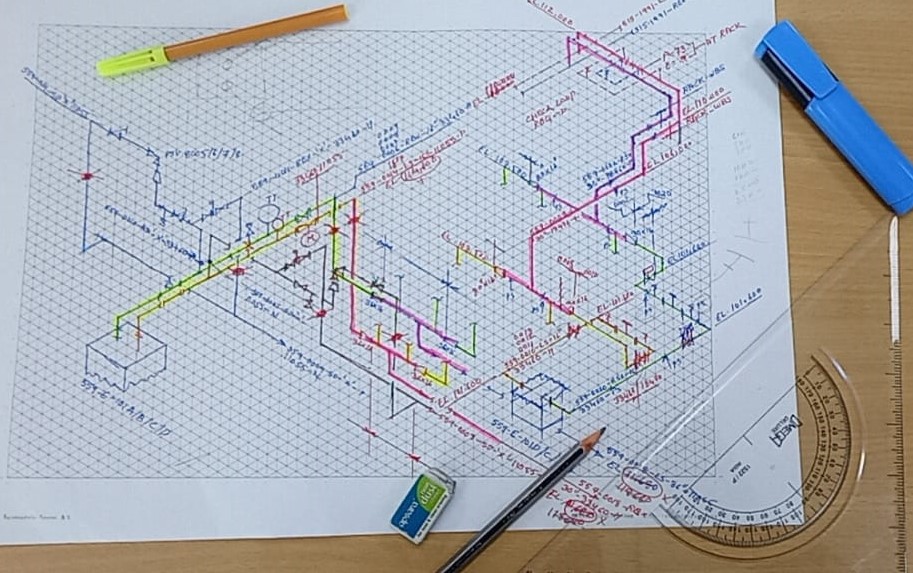

- Types of piping drawings, including P&IDs, isometric drawings, and piping plans

- Reading and interpreting piping drawings

- Documentation requirements for piping design projects, including specifications and design reports

7. Piping Layout:

- Principles of piping layout and routing

- Space allocation and optimization for different applications

- Design considerations for different industries, such as chemical plants, refineries, and power plants

8. Piping Design Software:

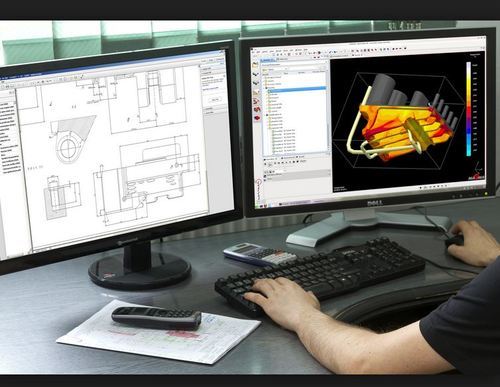

- Introduction to different piping design software tools, including 2D and 3D CAD software, hydraulic analysis software, and stress analysis software

- How to use software tools to design and analyze piping systems

9. Codes and Standards

- Overview of different codes and standards related to piping design, including ASME, ANSI, API, and ASTM

- How to apply codes and standards to piping design projects

- How to ensure that piping designs meet the required codes and standards

10. Case Studies:

- Real-world piping design projects and their challenges and solutions

- How to apply the principles and techniques of piping design engineering to solve practical problems in the industry

What is piping design engineering?

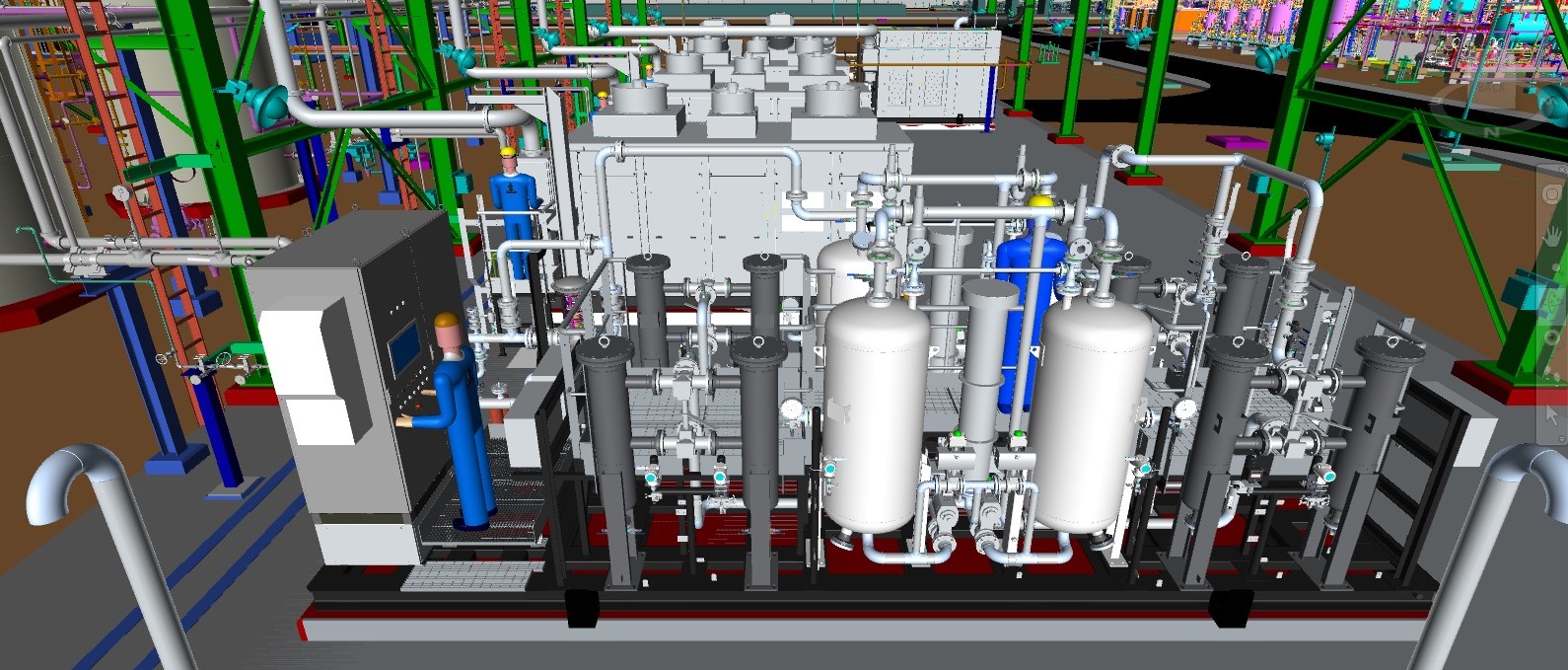

Piping design engineering is the process of planning, designing, and analyzing piping systems that are used to transport fluids or gases within industrial plants and facilities. These piping systems can range from simple, single-pipe configurations to complex networks of interconnected pipes, pumps, valves, and other components.

The goal of piping design engineering is to ensure the safe and efficient transportation of fluids and gases, while minimizing the risk of leaks, spills, and other potential hazards. This requires a thorough understanding of fluid mechanics, thermodynamics, materials science, and other relevant fields, as well as an ability to apply this knowledge to the design of piping systems that meet the specific needs of each application.

Piping design engineers are responsible for designing piping systems that are cost-effective, reliable, and efficient, while also adhering to safety and regulatory requirements. They use computer-aided design (CAD) software, mathematical modeling, and other tools to create detailed engineering drawings and specifications that show the layout, size, and materials of the piping system.

Overall, piping design engineering is a critical aspect of many industrial projects, and requires a combination of technical expertise, practical experience, and a strong commitment to safety and quality.

Piping design engineering

Piping design engineering involves the planning, layout, and analysis of piping systems used to transport fluids and gases within industrial plants and facilities. Piping systems can range from simple, single-pipe configurations to complex networks of interconnected pipes, pumps, valves, and other components.

The primary goal of piping design engineering is to ensure the safe and efficient transportation of fluids and gases, while minimizing the risk of leaks, spills, and other potential hazards. This requires a thorough understanding of fluid mechanics, thermodynamics, materials science, and other relevant fields, as well as an ability to apply this knowledge to the design of piping systems that meet the specific needs of each application.

Key tasks involved in piping design engineering include:

- Developing piping and instrumentation diagrams (P&IDs) that illustrate the layout and interconnections of the piping system components.

- Selecting appropriate materials and fittings for each part of the piping system, taking into account factors such as fluid composition, temperature, pressure, and corrosion resistance.

- Calculating the pressure drop, flow rate, and other key parameters of the piping system, using mathematical models and computer simulations.

- Designing supports and hangers to ensure that the piping system is properly secured and will not sag or move under its own weight.

- Coordinating with other engineering disciplines, such as mechanical, electrical, and civil engineers, to ensure that the piping system is integrated with other plant systems and meets overall project requirements.

Overall, piping design engineering is a critical aspect of many industrial projects, and requires a combination of technical expertise, practical experience, and a strong commitment to safety and quality.

Role of piping design engineer

The role of a piping design engineer is to plan, design, and oversee the construction and installation of piping systems used in various industrial facilities, such as oil refineries, chemical plants, power plants, and water treatment plants. Piping design engineers are responsible for ensuring that piping systems are safe, efficient, and meet the needs of the facility they are designed for. Some of the specific tasks that a piping design engineer may be responsible for include:

- Conducting feasibility studies to determine the most suitable piping system design for the intended application.

- Developing piping and instrumentation diagrams (P&IDs) to illustrate the layout and interconnections of the piping system components.

- Selecting appropriate piping materials, fittings, and valves for the intended application, taking into account factors such as fluid composition, temperature, pressure, and corrosion resistance.

- Calculating the pressure drop, flow rate, and other key parameters of the piping system, using mathematical models and computer simulations.

- Designing supports and hangers to ensure that the piping system is properly secured and will not sag or move under its own weight.

- Coordinating with other engineering disciplines, such as mechanical, electrical, and civil engineers, to ensure that the piping system is integrated with other plant systems and meets overall project requirements.

- Preparing detailed engineering drawings and specifications for the construction and installation of the piping system.

- Overseeing the construction and installation of the piping system, ensuring that it is installed correctly and meets all safety and quality standards.

- Conducting tests and inspections to ensure that the piping system is functioning correctly and meets all regulatory requirements.

Overall, the role of a piping design engineer is critical in ensuring that piping systems are safe, efficient, and effective, and meet the needs of the industrial facility they are designed for. This requires a combination of technical expertise, practical experience, and a strong commitment to safety and quality.

Company names who Recruit Piping Engineers

There are many companies that recruit piping engineers. Here are a few examples:

- Oil and gas companies such as Shell, BP, ExxonMobil, and Chevron

- Engineering and construction firms such as Fluor, Bechtel, Jacobs, and KBR

- Chemical companies such as Dow, BASF, and DuPont

- Power generation companies such as General Electric and Siemens

- Water treatment companies such as Veolia and Suez

- Manufacturing companies such as Caterpillar and General Motors

- Shipbuilding companies such as Huntington Ingalls Industries and BAE Systems

- Consulting firms such as Wood, Worley, and SNC-Lavalin.

These are just a few examples, as there are many other companies that require the services of piping engineers in various industries. It’s important to note that job opportunities for piping engineers can vary depending on the industry, location, and economic conditions, so it’s always a good idea to research companies and job markets in your area of interest.

Some examples of Indian companies

Here are some examples of Indian companies that recruit piping engineers:

- Reliance Industries Limited

- Larsen & Toubro Limited

- Tata Projects Limited

- Engineers India Limited

- Hindustan Petroleum Corporation Limited

- Oil and Natural Gas Corporation Limited

- Bharat Petroleum Corporation Limited

- GAIL (India) Limited

- Indian Oil Corporation Limited

- Adani Group

These are just a few examples of Indian companies that hire piping engineers. Other industries that may require piping engineers in India include power generation, water treatment, and manufacturing. It’s always a good idea to research companies and job markets in your area of interest to find opportunities that are a good fit for your skills and experience.

Future prospects for piping design engineering

The future prospects for piping design engineering are positive, as the demand for piping systems continues to grow across a range of industries, including oil and gas, petrochemicals, power generation, water treatment, and more. Here are some specific factors that may contribute to the future growth of this field:

- Increasing demand for energy and resources: The growing global population and increasing industrialization are driving demand for energy and resources, which in turn drives the demand for piping systems to transport these resources.

- Advances in technology: Advances in technology, such as new materials, software tools, and manufacturing techniques, are enabling the design and construction of more efficient and effective piping systems.

- Aging infrastructure: Many existing piping systems are reaching the end of their lifespan, creating a need for replacement and renovation projects.

- Focus on sustainability: As concerns about climate change and environmental impact continue to grow, there is increasing interest in developing sustainable and environmentally friendly piping systems.

- Regulatory requirements: There are strict regulations governing the design and construction of piping systems in many industries, creating a need for piping design engineers who can ensure compliance with these requirements.

Overall, the future prospects for piping design engineering appear to be strong, as there is a continued need for new and upgraded piping systems across a range of industries. This creates opportunities for skilled piping design engineers who can develop safe, efficient, and cost-effective solutions to meet these needs.